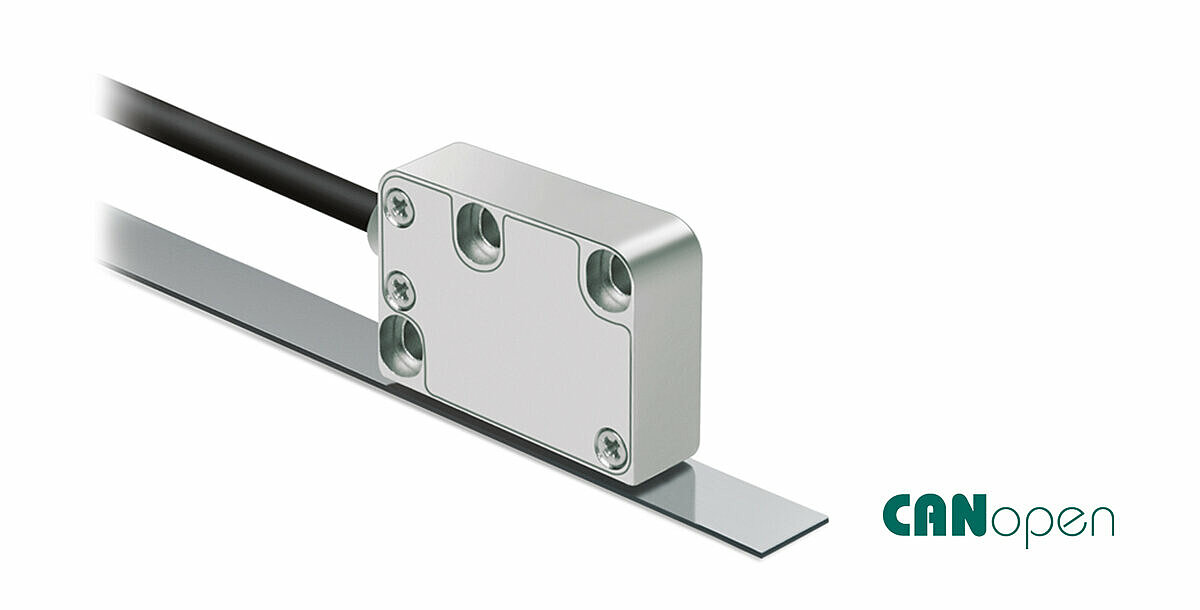

Magnetic sensor MSK5000CAN

Bearingless, compact, robust: the MSK5000CAN encoder from SIKO performs well in dynamic applications

The requirements in the world of mobile automation are increasing all the time. Precision, reliability and efficiency are crucial in rising to the complex challenges of highly automated and autonomous construction and agricultural machines as well as industrial trucks. At bauma 2025, SIKO is unveiling its bearingless MSK5000CAN encoder, which has been specially designed for these requirements and combines advanced magnetic measurement technology with the latest interfaces to offer machine manufacturers an efficient and cost-effective solution for measuring speed, direction of travel and position.

With the MSK5000CAN, SIKO is presenting an extremely affordable sensor for measuring the speed, direction of travel and position of mobile machines at bauma 2025 in Munich. The sensor measures incrementally and is equipped with the digital CANopen interface, meaning that it can be integrated easily into the cable harness and existing CAN networks in the vehicle. The distinctive feature is that it can be combined with a magnetic strip for linear applications or a magnetic ring for rotational measurements. At the same time, the bearingless encoder offers a very high IP protection type with its fully cast electronics. Even at high speeds, the rotary encoder remains reliably protected against penetrating water, dust and other media, and is therefore ideal for mobile machines.

Impressive value for money The MSK5000CAN performs well in commercial vehicles and AGVs

In comparison to absolute systems, the MSK5000CAN offers a more affordable alternative without compromising in terms of precision. With a maximum resolution of 5 μm and a repeat accuracy of ±0.01 mm, it is perfect for applications in which high measurement accuracy is necessary. Its price advantage and ease of connection to existing bus systems make it a favourite for commercial vehicles and AGV systems. In comparison to rotary encoders with bearings, bearingless encoders also offer an extremely space-saving solution thanks to their low installation depth. With its compact design and easy integration of large shaft diameters, it can be installed with ease into existing machines or drives.

High-precision speed and travel direction detection An AGV system has to navigate precisely around a complex warehouse, reliably recording its speed and direction of travel, and thus ensuring optimal coordination of the work process. Every movement must be monitored exactly, every change in direction must be detected precisely. This is exactly where MSK5000CAN reveals its strengths. With its CANopen interface, it communicates seamlessly with the vehicle control system, provides precise data about speed and direction, and thus ensures high efficiency and safety in operation. For vehicles in which fail-safe operation is particularly important, a second reading head on the magnetic ring or strip can easily provide redundancy.

Innovative magnetic measurement technology for construction and agricultureThanks to its advanced magnetic measurement technology, the MSK5000 combines high signal accuracy with outstanding robustness. Dirt, dust and temperature fluctuations have no effect on the sensor – which makes it perfect for challenging tasks in the construction industry and agriculture. With a reading distance of ≤2 mm, installation is very straightforward. The encoder also impresses in dynamic applications with its reliable performance. Thanks to the robust design and contactless measurement principle, the MSK5000CAN is maintenance-free and made for many years of operation under extreme conditions.