Intelligent Format Adjustment for Greater Process Reliability in Pharmaceutical Production

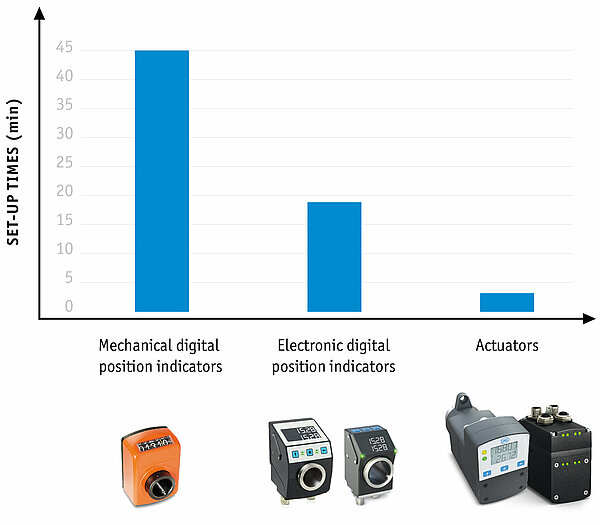

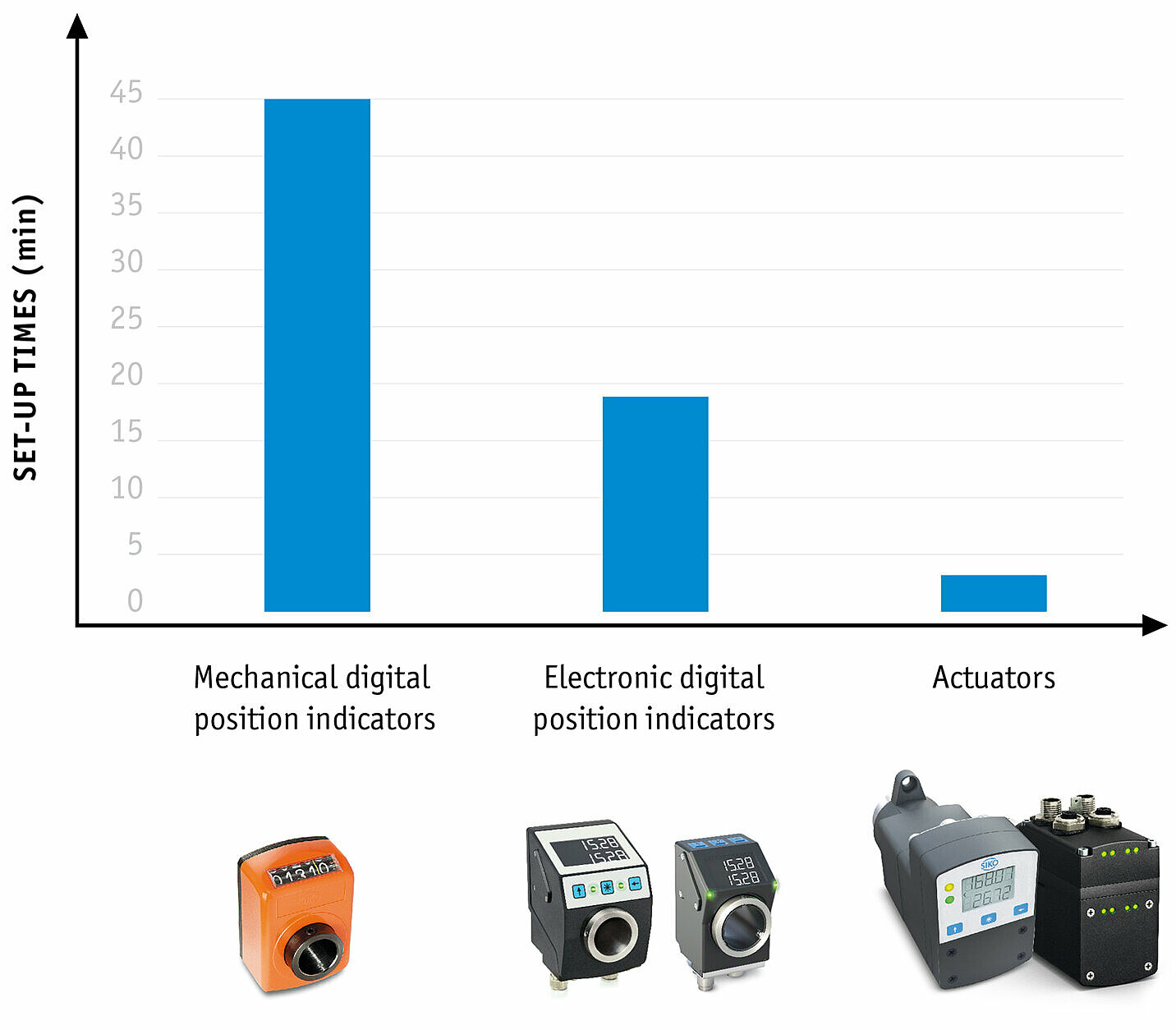

A factor that cannot be underestimated in the improvement of the system availability is the optimization of the changeover times during product changes in equivalence test format adjustment. There are various options for intelligent format changeover that contribute to the centerlining idea of optimized settings: from a simple purely mechanical solution for individual adjustment points to fully automated positioning systems for the entire system.

What format adjustment means

Format adjustment is present everywhere in the manufacture of pharmaceutical products. Whether for packaging, labeling or inspection, the term format is used when a new dimension is set on a machine for a new product. Not only through automation is a change of axes necessary for every machine as soon as the product or its dimensions are changed. Formats can be adjusted either manually via a crank or fully automated. The more individual the requirements are, the more intelligent, highly efficient format adjustment is required.

The most common variant of format adjustment is spindle adjustment, e.g., for packaging and labeling machines. The format or the axis of the machine is adjusted by means of the rotary movement of a spindle. This can be done manually via a crank or a handwheel or fully automated via a servomotor.

A linear guide is used where no spindle is available. In this case, a carriage is pushed over a rail and the new position is set via this mechanical construction. For this purpose, a lot of tact and sensitivity is required during the manual adjustment to achieve correct adjustment.

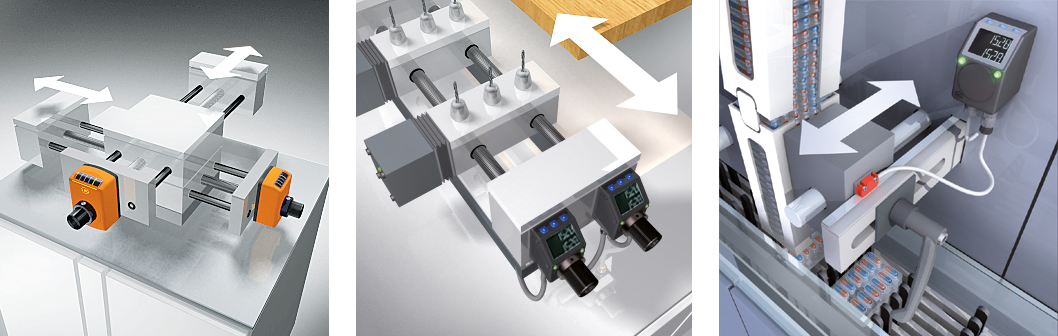

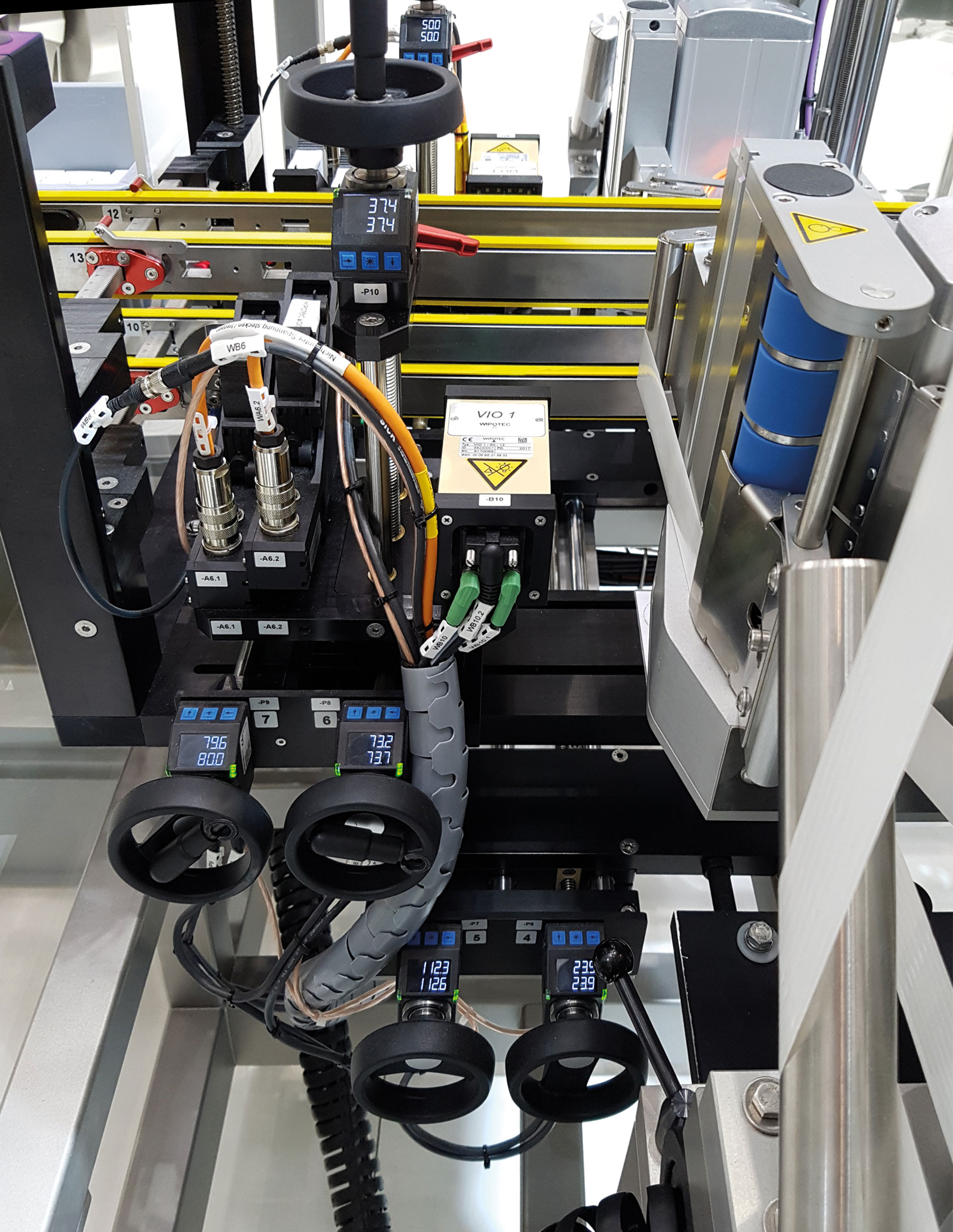

Schematic representation of manual format adjustment via mechanical-digital position indicators, Schematic representation of manual format adjustment via bus-compatible, electronic position indicators, Schematic representation of manual format adjustment via bus-compatible, electronic position indicators on linear guides

Using optimized format adjustment

Changing the settings of a machine always involves certain risks of proceeding incorrectly. With optimized format adjustment in terms of monitoring or even automation, this risk can be eliminated and flexible requirements can be reacted to better for the production processes.

The optimization of the format adjustment is intended to increase the repeatability. A product should be present again in the same form and quality after a change, even if it is produced again. This is a decisive criterion for the manufacture of medicinal products.

One effect that results from optimizing the speed of setup times is a significant reduction in costs. It is most noticeable in monitored and fully automatic format adjustment.

In addition to reproducibility and cost reduction through speed, an increase in process reliability is another argument for optimizing format adjustment. Position status is displayed clearly by LED lights monitored format adjustment; green means “position correct”, and red signals “position incorrect”. This makes it possible to program the machine so that it only resumes production when all positions are correctly set

Increased security in critical applications

There are applications in the pharmaceutical sector, in which it must be ensured 100% that the correct position is reached after format adjustment, regardless of whether this takes place once a week or hourly. Monitored format adjustment is indispensable there. For example, in machines, packaging sizes for medicaments are set. To do this, the labeling of the drugs must be updated in accordance with the new packaging to ensure clear traceability of the production process. All these aspects are adjusted via a format setting.

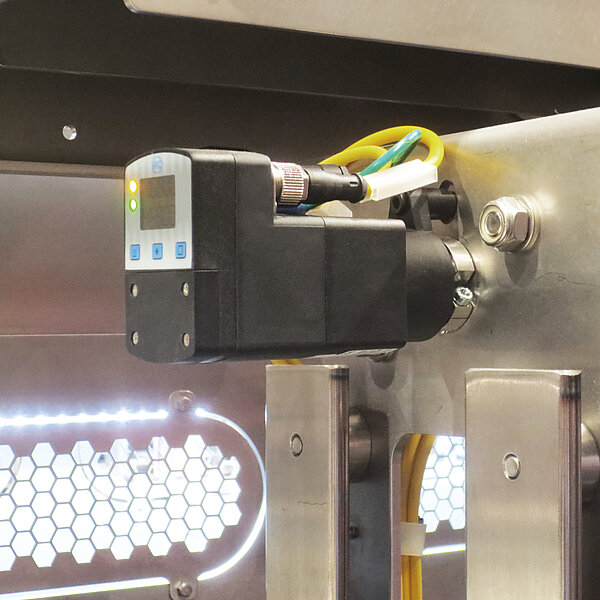

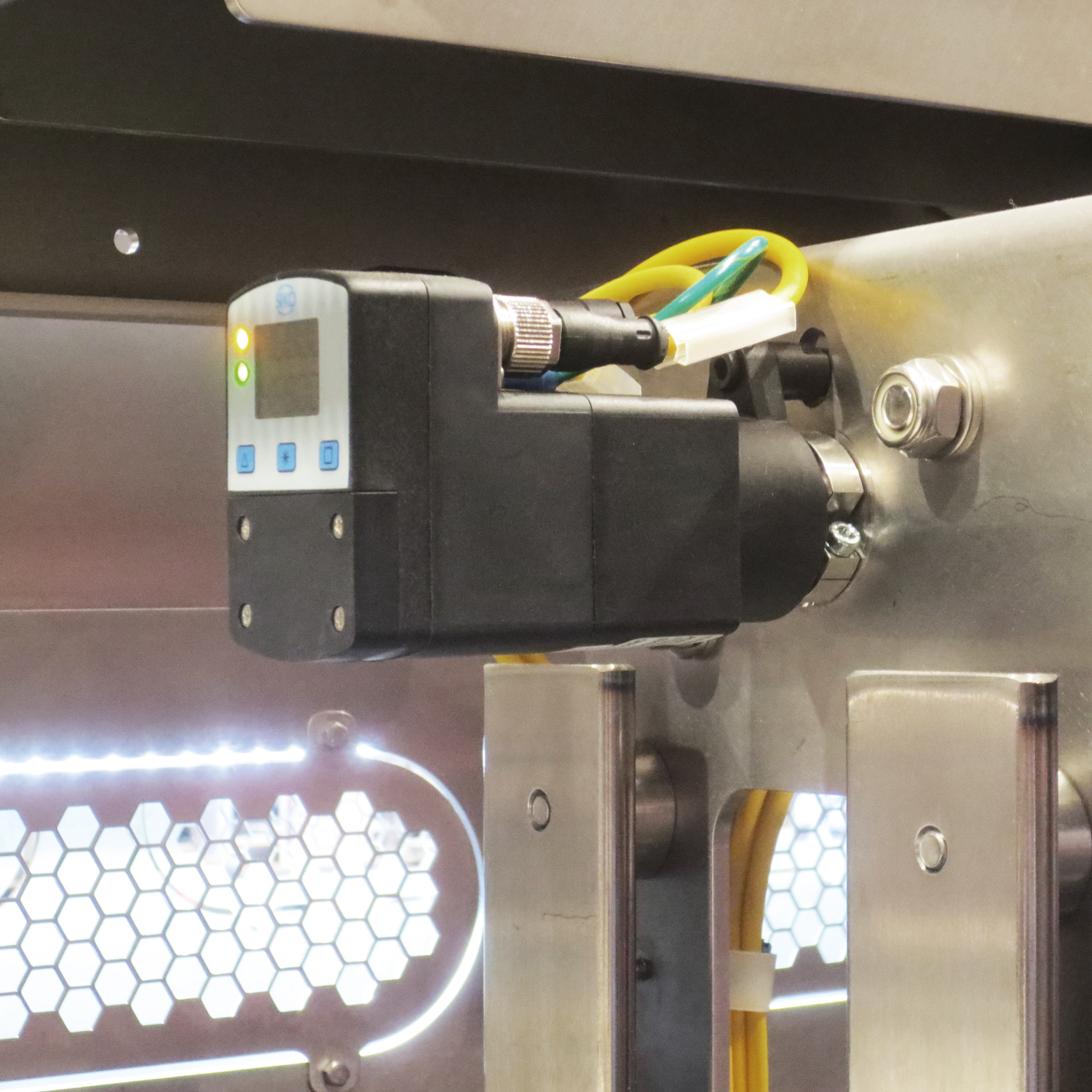

Another exemplary application is height adjustment for an inspection camera. The position of the camera must be adjusted to different product heights so that inspection can function with 100% reliability.

Manual format adjustment

Manual format adjustment is predestined for basic machines with rare format adjustments. Mechanical-digital or electronic position indicators are used that determine the positioning inexpensively and reliably.

In each position display, the core element is a measuring system that is used to record the position. The measuring system has a high accuracy, typically with a tolerance of approximately ± 0.5 degrees with respect to the rotary movement on the adjusting unit. A position indicator also provides controllable digital display values.

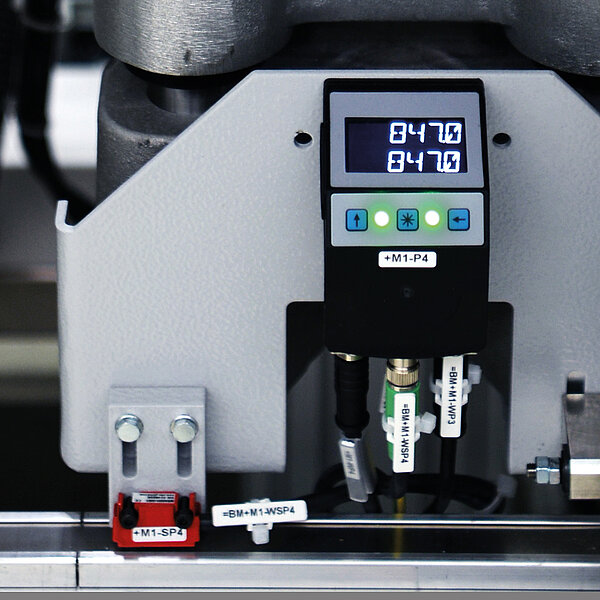

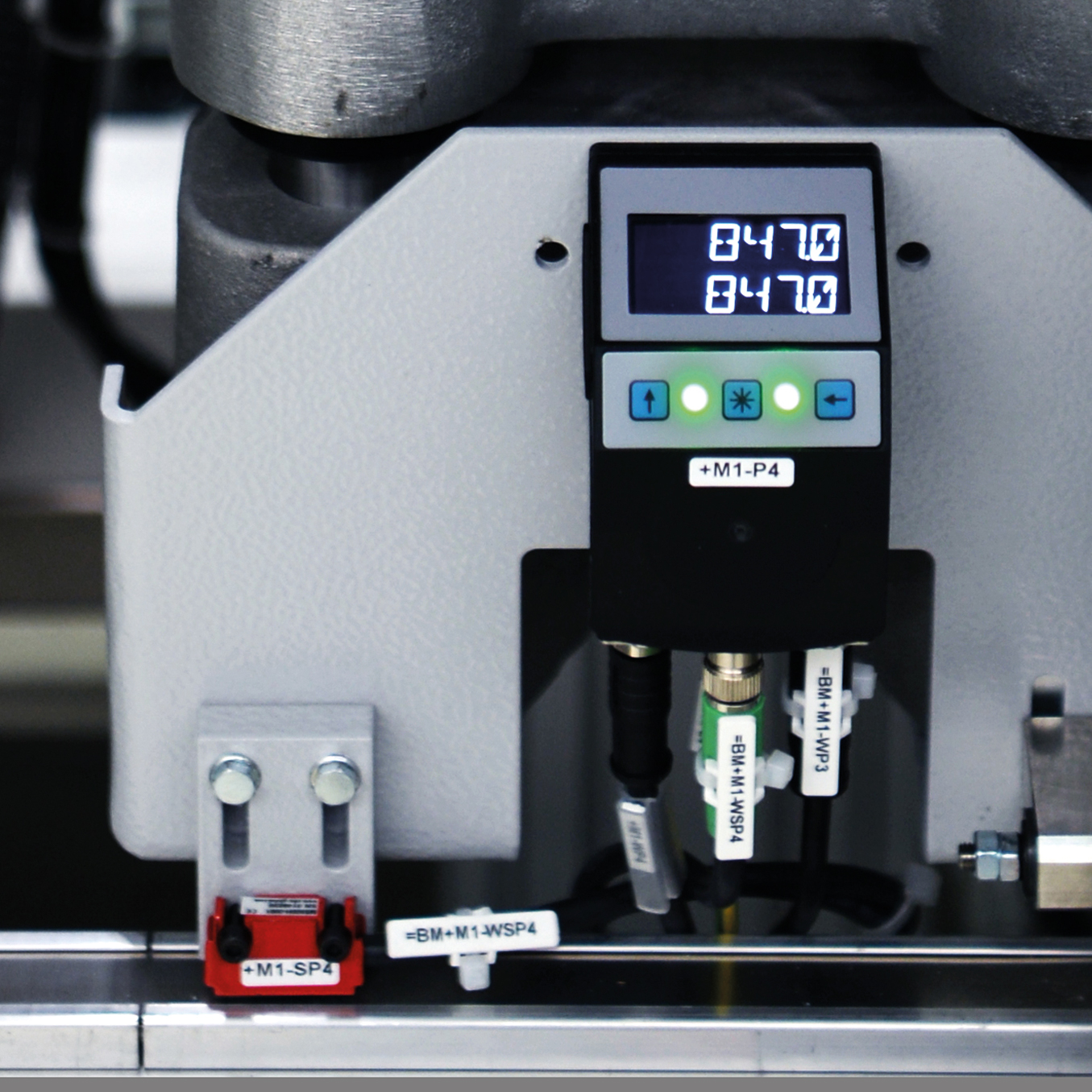

In addition to the measuring system, a position indicator also includes a display. One variant is a mechanical-digital position indicator, which represent the values in decimal places in powers of ten in the form of number drums. Therefore, the term “digital” is used, although it is not an electronic display. On the other hand, electronic position indicators have an LCD display. The AP series is used when it comes to monitored format adjustment, which additionally show the setpoint value in the second display line.

Absolute measurement principle and calibration

The position indicators operate according to an absolute measuring principle that does not have to be constantly referenced, i.e., the indicator detects movements on the adjusting unit even in a de-energized state. In the case of the electronic position indicators – either as stand-alone or networked – this is done via a battery, i.e., these operate according to an absolute measuring system that is battery-buffered and only needs to be referenced once.

Resolution and accuracy

The resolution indicates the smallest readable measurement step that the display provides; in the case of the electronic displays with setpoint specification, for example, there are 720 increments per revolution, which ensures high reproducibility.

Mechanical-digital position indicators

The position values can be recorded with high precision and are displayed in a clearly legible manner. The display value per revolution is appropriately designed via an integrated gear for the respectively required spindle pitch. The special feature of mechanical position indicators is their exclusive suitability for a particular application. A specific device variant is configured for an application with a specific spindle pitch in a desired resolution.

Electronic position indicators LCD stand-alone

The decisive advantage of the electronic position indicators compared to mechanical-digital ones is free programmability for flexible use. A variety of parameters can be configured freely via the position indicator: the spindle pitch, the decimal points, the direction of rotation, the installation position, and use in angular mode.

Compared to the mechanical-digital position indicators, even higher resolutions can be achieved with the electronic indicators. The transmission ratio is limited for the mechanical ones. In contrast, up to 3,600 counting steps per revolution can be realized with electronic displays. A division into tenths of a degree is thus easily possible. Positive in the balancing between mechanical or electronic position Indicators is the enhancement compatibility between the two, so a conversion or extension is unproblematic.

Monitored format adjustment with electronic position indicators

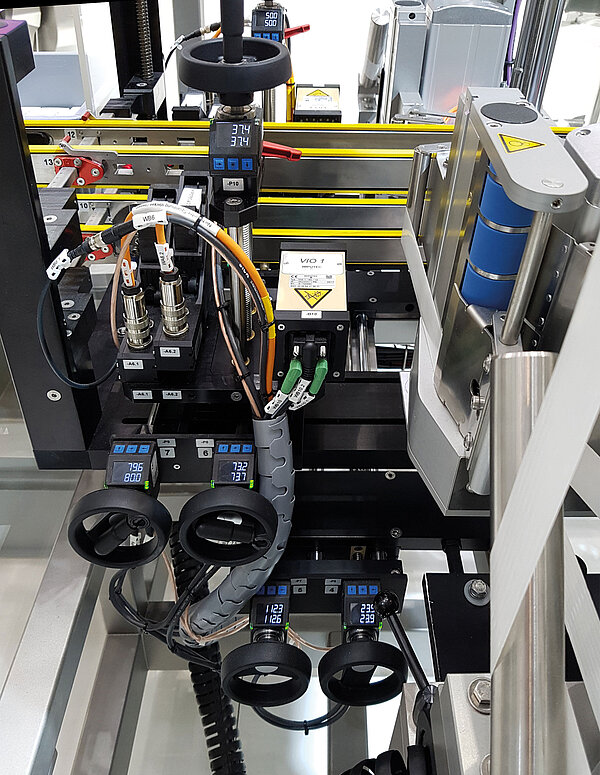

Electronic position displays with setpoint specification and bus communication are used for monitored format adjustment. In bus-controlled operation, setpoint values and actual values can be exchanged between the individual absolute position indicators and an upstream control unit.

Basic requirements for process stability

While manual format adjustment focuses on the requirement of reproducibility, monitored format adjustment is primarily concerned with process stability. This is achieved centrally via the machine control (PLC) thanks to the bus integration of the position indicators. The PLC is the leading element that sends setpoint values to the position indicators and reads the measured actual values. Based on the transmitted position status, it only releases the entire system after correct feedback of all manually set spindle positions, so that rejects or damage to machine modules due to incorrectly set adjustment axes no longer occurs. Machine and economic efficiency of the production facilities also increase significantly thanks to monitored format adjustment with bus-enabled electronic position indicators.

These receive their basic parameterization from the machine control via fieldbus and the respective setpoint position to be set at the time. The setpoint values are stored in formula management within the machine control, i.e., a formula with all necessary setpoint values such as length, height, and width of a folding box or packaging is located in formula management for each product to be manufactured. For this, various adjustment positions are necessary.

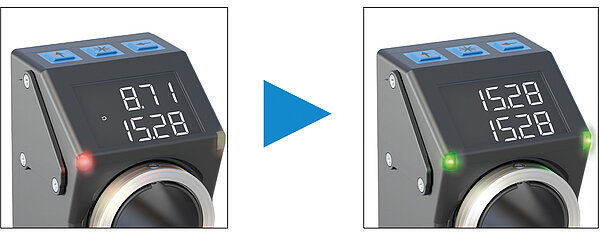

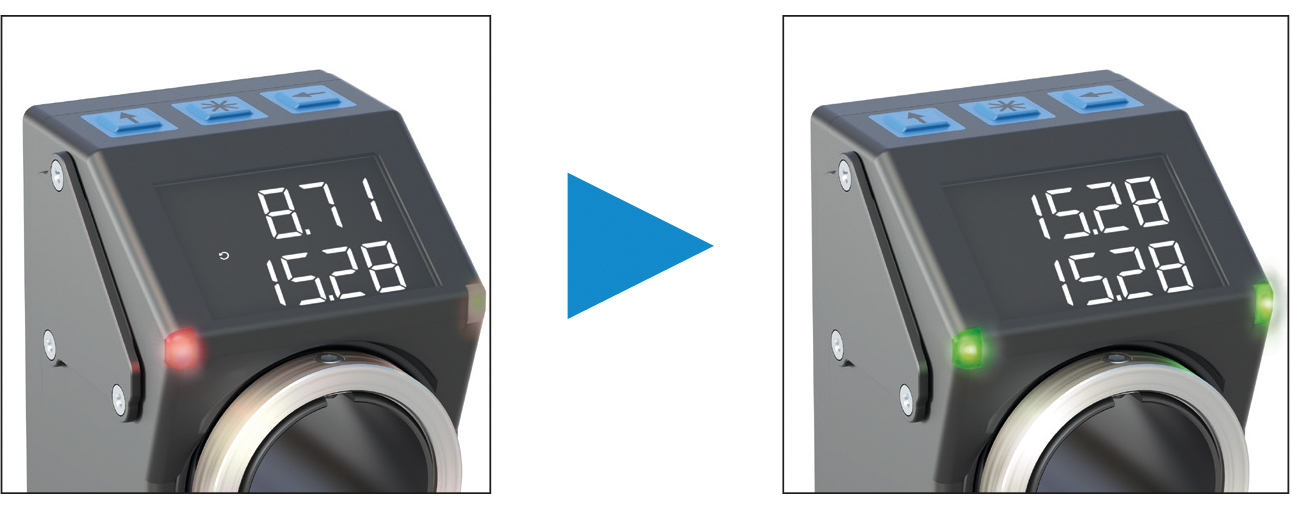

Position status display

The machine control specifies the setpoint values, which are also displayed on the position indicator in the second line. The special feature of the monitored format adjustment is also the two LED lights, which clearly indicate position status with green for “position correct” and red for “position incorrect”.

The LED function and an integrated arrow direction display also have a positive effect on ergonomics and ease of use. Thanks to the arrow direction display, it is clear to the operator in which direction the adjustment has to take place. He does not have to interpret numerical values to find the target position, but instead only the LEDs with direction display are necessary.

Applications

Applications for monitored format adjustments are available in a wide variety of fields of pharmaceutical mechanical engineering. The format adjustment is particularly typical when setting the packaging sizes for the cartoning machines and when labeling products. Under the European Anti-Counterfeiting Directive, prescription drugs must be clearly labeled using 2"Track & Trace” systems. Monitored format adjustment with bus-capable electronic position indicators increases the process reliability of these “Track & Trace” systems, which include the processes of printing, reading, labeling and weighing.

Monitored setpoint value displays

While the acquisition of the measured value constitutes a large part of the functionality in the electronic position Indicators for spindle adjustment and linear slides, format part change is exclusively about the display of the pure setpoint value on site. However, the process reliability here depends heavily on the respective operator, who must insert and at the push of a button acknowledge the correct format part.

Automatic format adjustment

The next step beyond the monitoring of the format adjustment is the complete automation of the adjustments without manual intervention via compact actuators. There are two reasons for automation: On the one hand, the changeover times are significantly reduced, which is particularly useful in the case of frequent product changes. On the other hand, there are often axes which are difficult to access and which can be reached only via a ladder or only by removing covering parts, so that automatic adjustment simplifies matters.

The basic idea of an actuator is its highly integrated design, via which “all” components are present in the device itself: a brushless DC motor (which is wear-free), a low-play and high-performance gear, a position encoder as well as power and control electronics. As a result, the actuator can be connected directly to the control Thanks to the integrated hollow shaft, the actuator can also be easily adapted to the existing spindle.

Various standard interfaces enable direct communication with higher-level machine control. This functions as a control center, which specifies the setpoint values and also the start command to the drive. However, fully automated positioning is controlled within the drive with respect to setpoint value and speed, among other things.

Different performance classes

The bandwidth of format adjustments is relatively large. It begins with simple fine adjustment, for example, where a fine adjustment is carried out by means of a small rotary knob during manual adjustment in a folding box magazine in the packaging process,. Only low torques are required in this context. Therefore, small drives with a low power requirement can be used.

The other extreme is shown in packaging machines, for example, where complete feed systems for cardboard boxes must be adjusted in width depending on the packaging size, i.e., entire machine units must be moved. Relatively high torques are required for this.

A typical application in the pharmaceutical packaging sector is a cardboard erector, by which the folded cardboard boxes are erected into boxes. Drives from the medium power range between 50 and 70 watts are suitable for this application.

Process Data Exchange

Actuators basically operate in two different modes, which are considered standard operating modes: positioning mode and speed mode. In the positioning mode, the setpoint value is transmitted from the controller to the drive. This then automatically moves the item to the desired position with the speed previously requested by the control until it arrives there. In the speed mode, the controller only predetermines a speed and direction and then permanently monitors the actual value until the setpoint position is reached. When the drive comes close to the position, the controller decreases the (rotational) speed.

An important safety function is that the machine does not function again until all axes or drives have found their respective position. When the position is reached, a corresponding bit is set in the message communication for control as confirmation of the position. In addition, the controller could also read back the actual value on the drive and compare it with the setpoint value. If they both match, the controller can initiate resumption of production.

Flexible thanks to parameterization

Numerous parameters can be defined via the bus interface to be able to adapt the drive optimally to the respective application. The simplest parameter is the setting of the adjustment in millimeters. For this purpose, the programmer must know how much linear path is moved on the axis per revolution. This parameter can be stored in the drive.

In addition, acceleration and braking ramps can also be programmed, so that you can specify how quickly the drive accelerates and how quickly or slowly it brakes again. This is important for accurate positioning, so that it does not move beyond the desired position. The maximum current can also be set as a parameter to limit a certain torque. In this way, certain safety precautions can be guaranteed.

Predictive Maintenance

The diagnostic capability that lies in the actuators is hidden behind this aspect. Conclusions can be drawn about the operating state of both the drive and the system itself via various display values and parameters of the drive to detect irregularities or maintenance requirements at an early stage. For example, current consumption in the motor, the temperature or the voltage values on the control and load circuit can be monitored, so that measures can be initiated at an early stage if the values are exceeded.

Network integration for intelligent format adjustment

In the case of network integration, a certain compatibility with the already existing machine control is required when selecting the interfaces. In a Siemens control system, for example, it is simplest to integrate a device with a Profibus or Profinet interface. RS485 and CAN have long been established, cost-saving serial interfaces. Numerous field devices can be networked over large distances at a relatively high speed using them.

IO-Link is a serial, bidirectional point-to-point connection for signal transmission and power supply in any network or fieldbus. In recent years, IO-Link has already become widely used, especially in European mechanical engineering. Several, usually up to eight, IO-Link field devices are then connected star-shaped to each IO-Link master. Commissioning is greatly simplified by the point-to-point connection, since IO-Link devices do not have to be addressed. In addition, if there is a fault, it can be quickly located and has no effect on other field devices.

BeModern industrial Ethernet interfaces have a very high reaction rate. Any desired topology can be used, and a ring structure is also possible. This increases operational safety, because all subscribers can be reached on both sides, which is particularly decisive in the event of an interruption of the connection. Comprehensive process and diagnostic data exchange are possible via the industrial Ethernet interfaces, which also supports measures for “predictive maintenance”.

Summary and Outlook: More Automation, More Data

The requirements for the flexibility and availability of machines and systems in the pharmaceutical sector remain high. Consequently, the need for intelligent format adjustment will remain. The trend in drug production is toward smaller batches and more frequent product changes on the systems as a result. The degree of automation in the machines will certainly increase even further, also with regard to newer systems such as “Track & Trace”, which are intended to ensure the traceability of drugs. Supporting components are thus becoming increasingly important, by means of which adjustments between different product sizes can be carried out quickly, in a controlled way and in a process-reliable manner,. Process reliability is especially crucial in the manufacture of medicine. By means of a monitored or automated format adjustment, the susceptibility to errors due to the "human factor” can be reduced further.

More intelligence and connectivity for Pharma 4.0

Peripheral components such as indicators and actuators will play a greater role in the further development of intelligent and flexible solutions for production systems. In addition to the actual process data, it is helpful if the components mentioned collect even more information about the operating state of the system. The indicators and drives could take then measures independently, so that warning messages are sent or the power of a drive is reduced if limit ranges are exceeded, for example. The topic of self-diagnosis will certainly become even more important in the future for these components. This can extend up to the lifetime monitoring, so that data are also collected internally and the peripheral module develops into a data logger.

Approx. 22,000 characters (incl. blanks)

Author: Jürgen Schuh, SIKO GmbH, Head of the Changeover Solutions Business Unit